Low volume injection molding

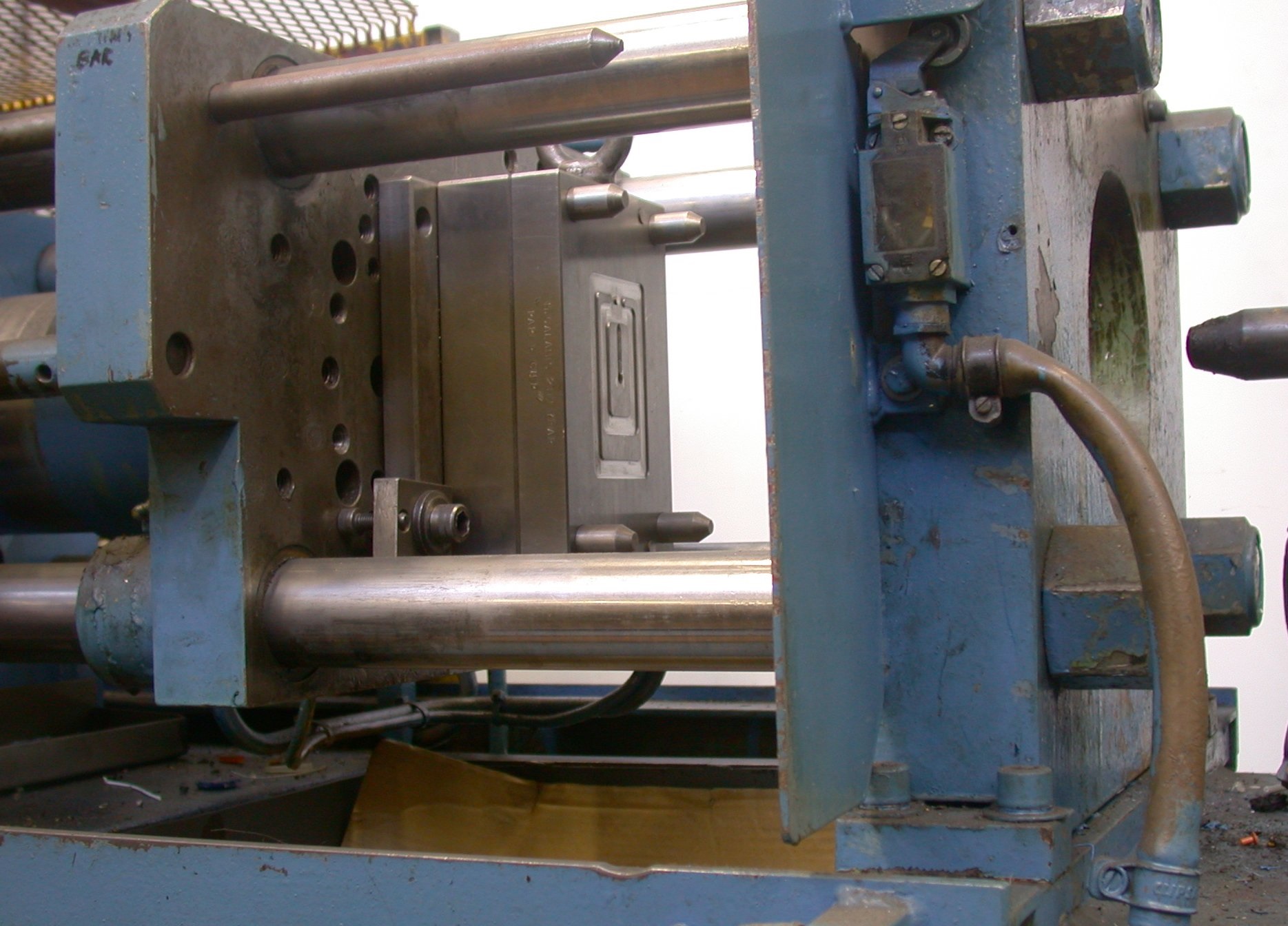

Injection mold which is used for manufacturing the plastic and fabricated items. The manufacturing process provides items such as plastic trinkets, plastic toys to the automobile body parts. It also includes cell phone cases, water bottles, and other foodstuff containers. The process of molding things with the plastic parts that are used for various functions. The Low volume injection molding plastic is made with the injection-molded process of it. The quick process is to create a mass amount of plastic parts that are identical to it. They are flexible in shape and size to achievable for all sort of molding design in plastics.

The process of flow volume injection molding is which they are short runs with specialized service offering the full production parts. The output process is less ion quantity but higher in the quality level of it. The product is allowing you to limit the investment in the usage of the material and buying the resources forms others. It Low volume injection molding increases the more designs and much flexibility for limiting the investment in the products. The production can be increased by this method and function of it.

Contrary to popular belief, it’s not always true that buying in bulk saves money. It may be true for household items, however, when it comes to manufacturing; cost per unit is highly dependent on the materials that are being used. The large-volume production facilities can impose minimum order specifications to cover set up costs and offset heavy production investments. Low volume injection molding has much lower overhead, and products can be made without the demand for a minimum order. This is particularly helpful for customers looking to get a part or product created on a small scale, and if they know the design may change in the future. This will also withdraw being overwhelmed with outdated inventory created by a large manufacturer’s smallest order conditions.

Being the first to the market with a product can be the deciding factor between success and failure. A highly competitive market leads to an increasing amount of pressure on developers and manufacturers to create high-quality products in very little time. The markets that must be adhered to special rules and commands, like medical products must meet the regulations, it’s important that a company can quickly remove inefficiencies and give quality ideal parts in a matter of days. Ensure a manufacturer has up to date software, to review your part design. The one standardized system helps to quote your project quickly and correctly while seeing potential difficulty areas before the mold is made.

Since products are manufactured in smaller quantities within short-runs, it doesn’t significantly impact the whole order if a company wishes to alter or modify the design. A quality manufacturer should provide immediate design feedback to improve the manufacturability of the parts when the quote is delivered. They accelerate the process and remove possible visual or performance defects before the first parts are created. Low-volume manufacturing is common in the medical device and life sciences fields, as new concepts are tested in pilot markets or clinical trials before reaching consumers or mass production of the product.