The Importance of Cutting Tools in Machine Industries

Cutting tools involve a wide range of products and materials, such as drills, taps, and lathes, to shape or cut the material into fabrications that fulfill specific purposes. Quality-cutting tools offer greater speed in shop floor operations while saving you time and money on setup costs. With advancements in automation technology over recent years, productivity increases have been made possible with higher precision machines becoming available and better quality control systems implemented across many businesses worldwide.

The best way to ensure a successful outcome from your machining operation is by investing relatively small amounts at the start to get access to high-grade, durable tooling options necessary for future success rates.

Quality Cutting Tools for Optimal Machining

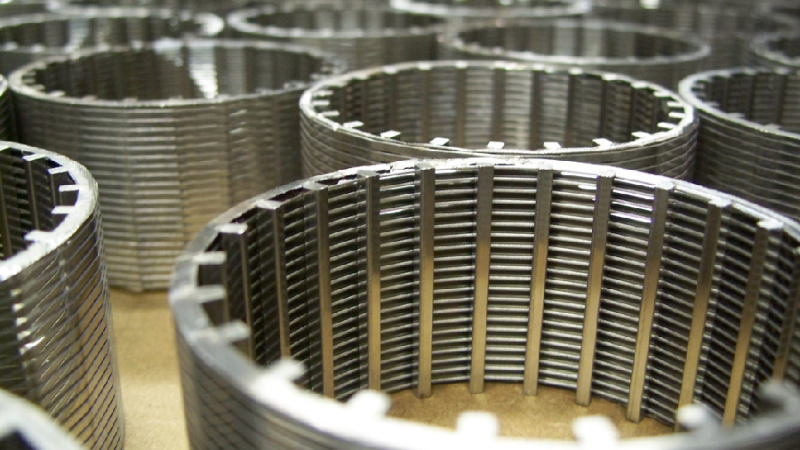

Cutting tools are a crucial part of machining, contributing to the quality and efficiency of metal parts. These tools come in various shapes and sizes, which can be tailored for different applications depending on your needs. The right cutting tool can give you better performance with reduced cycle times at an optimal cost-efficiency level while still maintaining excellent precision.

Choosing high-quality cutting tools is essential if you want consistent results in manufacturing projects, whether small-scale or large-series production tasks. Suncoast Precision Tools understand that you need dependable products delivered quickly and safely, so safety elements such as built-in coolant channels and features like efficient chip evacuation during operation have been considered.

The Role of Cutting Tools in Machine Industries

Modern machine industries require high levels of precision, which has been made possible through better-quality tools that can hold tight tolerances even at higher speeds.

The use of advanced technology in manufacturing offers improved performance when it comes to producing components for machines quickly and efficiently. To achieve this goal, the right type of cutting tool needs to be selected for each application, designed specifically for its purpose, and consistently produce reliable results over time.

Selecting an appropriate tool is only one part of ensuring an optimal working environment during industrial operations. Other important aspects, such as proper lubrication technique, feed rate control, and coolant management, should all be done according to material specifications. This will minimize heat generation while maximizing production output without risking breakage or deformation of the final product due to unexpected increases in pressure, thus avoiding any safety hazards for the operator or workpiece itself.

Hence, utilizing best practices across all areas ensures a smooth-running operation and greater efficiency, ultimately leading to better productivity within the industry and achieving desired business objectives proficiently.

Cutting tools are essential for efficient and precise machining operations in the industrial sector. Suncoast Precision Tools has a wide range of cutting tool solutions designed to meet your production needs, from milling cutters, carbide inserts, and taps to hole-making products like drill bits, reamers, and countersinks. The company can provide you with quality machine tools that offer sharp edges while accommodating higher speeds due to the hard-wearing construction materials used within them.

This improves productivity by decreasing downtime when it comes time for cleaning or resetting equipment parameters since they require less adjustment than traditional machines. Their precision technology capabilities also allow for better control over the workpiece surface finish, resulting in excellent repeatability between projects! So, if you’re looking to get top-grade machinery at competitive prices, be sure to give Suncoast Tools an inquiry today; they’ll help get your manufacturing operation running smoothly without any hassle!