WHAT IS A POGO PIN?

A pogo pin is an electrical connector used in modern electrical applications and testing solutions. Its electrical connection is very resilient to mechanical vibration and shock, which improves their durability over other electrical contacts.

How does a pogo pin work?

A pogo pin socket integrates with a helical spring in the pin that applies force at the back of the contact plate or mating receptacle. It counteracts any unwanted movement that may cause an intermittent connection.

For the connection path to be complete, a mating receptacle must be required for the pin to engage, which is called a land or target. A pogo target contains a flat metal surface that has no moving parts, unlike the pins.

In the case of a printed board circuit, the target can be a plated area of the board or, in some cases, targets can be separate areas in the complete connector assembly.

It results in a secure connection which, is why technicians have widely used pogo pins as connectors in devices.

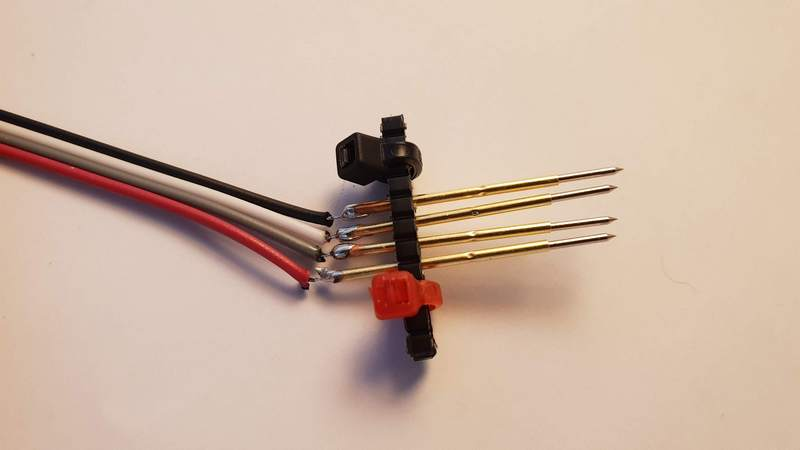

How is a pogo pin structured?

A spring pogo pin consists of three parts; a spring, plunger, and a barrel. When there is an application of force in the pin, the spring compresses, the plunger moves inside the barrel. The barrel’s shape maintains the plunger preventing the spring from pushing it out when the pin is not locked in place.

When designing electrical contacts, technicians use friction to hold a connector and maintain the contact finish. However, as with other devices, the force and friction strain the surfaces, causing wear and tear of the contact springs and enclosure.

While a spring-loaded pin needs to have a small gap between the plunger and barrel to help in sliding out easily, vibration and movements happen, which can trigger disconnections. To prevent the disconnection, the plunger is usually tilted slightly to ensure there is a continuous connection.

As a result, many electrical experts such as Test Tooling Solutions Group have modified or created variations of the pogo pin design. Most standard models vary the interface between the plunger and the spring.

For example, the plunger can have an angled tip, or a ball fixed between the two elements.

Spring-loaded connectors or pogo pins are useful in various ways, both consumer and industrial electricals.

OF WHAT MATERIAL IS A POGO PIN MADE?

Most pogo pins use copper and brass as the base material for the plunger and barrel. A thin layer of nickel usually coats on top.

Copper alloys or spring steel makes the springs.

In addition to that, like all other connectors, manufacturers apply gold plating on the plunger and barrel to improve its contact resistance and durability.

conclusion

Pogo pins provide great versatility when it comes to design. However, for you to take advantage of this, it requires careful selection and often customizable designs.